(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Linear Guides

A linear guide is a linear motion part for smooth motion in the direction of the rail without rattling.

Various manufacturers use different names, such as linear guides (MISUMI), LM Guides (THK), NSK linear guides (NSK), Linear Ways (IKO) and slide guides (NB).

■ Features

· MISUMI's linear guides are made by Suruga Production Platform.

An extensive lineup is available, including miniature to medium/heavy-load types, industry standard products and dowel hole types. The size, material and precision can be selected, and rails can be specified in 1 mm increments.

■ Peripheral parts

Cap, clamper, linear lock, stopper, block, bellows

Various manufacturers use different names, such as linear guides (MISUMI), LM Guides (THK), NSK linear guides (NSK), Linear Ways (IKO) and slide guides (NB).

■ Features

· MISUMI's linear guides are made by Suruga Production Platform.

An extensive lineup is available, including miniature to medium/heavy-load types, industry standard products and dowel hole types. The size, material and precision can be selected, and rails can be specified in 1 mm increments.

■ Peripheral parts

Cap, clamper, linear lock, stopper, block, bellows

Linear Guides

FAQ Linear guides

-

- Question: Do you have user manual?

- Answer: No.

Please see more details in General information for design and selection of Linear Guides - Question: What is allowable load?

- Answer: Allowable load consists of Basic dynamic load rating, Basic static load rating, and Static moment rating.

- Question: What is Basic dynamic load rating?

- Answer: Basic dynamic load rating is defined as: a load applied in a constant direction and ran under equal condition on a group of linear guide specimen where 90% of specimen will reach 50×10³m

This parameter also used for calculating the life span of Linear Guides in case of receiving load while moving. - Question: What is Basic static load rating?

- Answer: Basic static load rating is defined as: a load applied on non-moving linear guides where a sum of rolling element plastic deformation amount and rolling surface plastic deformation amount becomes equal to 0.0001 times that of the diameter of the rolling element.

This parameter also used for calculating the Static Safety Factor for load receiving. - Question: What is Static moment rating?

- Answer: Allowable static moment is a critical static moment load defined by permanent deformation value where a sum of rolling element plastic deformation amount and rolling surface plastic deformation amount becomes equal to 0.0001 times that of the diameter of the rolling element.

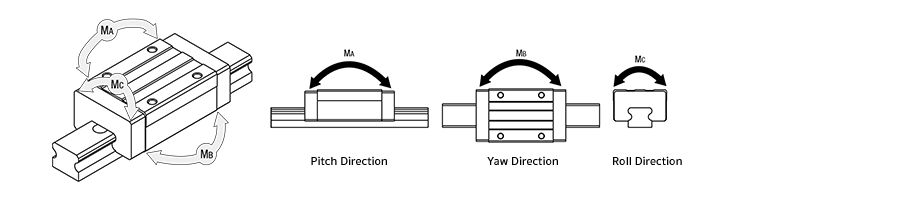

For Linear Guides, moment can be separated in 3 directions: MA MB and MC

- Question: What is Static Safety Factor?

- Answer: Static safety factors are given in Table-1. When a linear system is still or moving at low speed, basic static load rating Co must be divided by fs in accordance with the conditions of use.

Safety factors should be considered and provided for safety design. Please see the table below for reference:

Static Safety Factor(Lower Limit of fs)Condition of Use Lower Limit of fs Under Normal Operating Conditions 1∼2 When Smooth Travel is Required 2∼4 When Subjected to Vibrations, Impacts 3∼5 - Question: What is life span?

- Answer: Life span is measured in terms of the total travel distance covered by the system up until initial flaking occurs because of rotation fatigue.

- Question: What is Rated life span?

- Answer: Rated life span is the total travel distance that each linear system of the same series can endure under the same conditions, without the occurrence of flaking in 90% of the system.

Safety design should consider and provide for these factors. - Question: What is Flaking?

- Answer: Flaking is a type of failure caused by movement fatigue on the rotating surface or rolling element from tension force, cracking will be occurred on surface which looked similar to fish skin.

- Question: What is Correction factors?

- Answer: Correction factors are coefficient of safety when considering to several factors that applied to Linear Guides (change of moment of inertia or timing of load applied due to the hardness of rail, operating temperature, application, etc.)

Correction factors consists of Hardness factors, Temperature factors, Contact factors, Load factors. - Question: What is Hardness factors?

- Answer: Hardness factors is used for correction the rated life from hardness. Linear Guides required for Sufficient hardness for ball contact shafts. Insufficient hardness causes less allowable load, resulting in shorter life span.

- Question: What is Temperature factors?

- Answer: Temperature factors is used for correction the rated life from operating temperature. When using at high temperature, hardness of Linear Guide and shaft decreases, resulting in less allowable load and shorter life span than used at a room temperature.

- Question: What is Contact Factor?

- Answer: Contact Factor is used for correction the rated life from contact during operation.

For actual applications, more than 2 blocks are generally used per shaft. In this case, load applied to each block varies depending on machining precision but is not uniformly distributed. As a result, per-block allowable load varies depending on per-shaft Linear Guide quantity which also effect to safety and shorter life span. - Question: What is Load Factor?

- Answer: Load Factor is used for correction the rated life from load applied.

In generally, it is difficult to attain accurate calculations due to potential vibration and impacts. So, we have to determine this factor to simplify the calculation of load and life span. - Question: What is Precision?

- Answer: It is tolerance and fits between rail and blocks, consists of Running Parallelism, Pair Variation of Height, Pair Variation of Width, etc.

Theses accuracy and precision classes also one of the criteria for selection of tools and position in machining process. - Question: What is Precision classes?

- Answer: Precision classes are Precision Grade, High Grade, Standard Grade (High Precision or Ct5 Ct7 in some manufacturers) etc.

Precision classes also one of the criteria for selection of manufacturer.

Theses precision classes also one of the criteria for selection of tools and position in machining process. - Question: What is Preload?

- Answer: Clearance between Rolling element and Rotation surface. In generally, preload (minus clearance) will reduce flexibility deform and increase the rigidity.

In addition, preload should be determined with vibration and impacts from movement in order to reduce negative effect to life span and accuracy. - Question: What is Running Parallelism Pair Variation of Height Pair Variation of Width?

- Answer: Running Parallelism is a relative variation measured as the block run from end to end on the rail while the rail is bolted firmly to a standard reference.

Pair Variation of Height is difference between the min. / max. values of Height (H) Dimension for a number of blocks combined on one rail.

Pair Variation of Width is difference between the min. / max. values of Width (W) Dimension for a number of blocks combined on one rail. - Question: What is friction force?

- Answer: Friction force varies depending on load, speed, lubricant property etc. during Linear Guides moving.

Especially when moment load applied, Preload Type friction force increases. - Question: What is Rolling element?

- Answer: Balls or rollers between rail and blocks.

- Question: What is Rotation surface?

- Answer: It is rotating surface of Rolling element. This surface was finishing with high precision process.

Surface hardness must be HRC58∼64 or higher. If not, it is necessary to correct life span by Hardness factors. - Question: What is applied load?

- Answer: Actual load that applied to Linear Guides.

- Question: What is Average of Fluctuating Loads?

- Answer: In general, load applied to Linear Guides varies depending on their applications. For example, there are cases at the start and stop of reciprocating motion, during constant motion or transfer with/without a workpiece. Therefore, it requires average load under which the life equals to the one under these fluctuating loads.

- Question: What is Equivalent load?

- Answer: When many load applied in various direction, load must be projected into radial load or reverse radial load in order to calculate the life span and Safety Factor.

Equivalent load is the resultant of load after projected. - Question: Does the accuracy of MISUMI Linear Guides similar to Linear Guides of other manufacturers.

- Answer: If they are classified in the same Precision Class, accuracy will be equally or higher. However, MISUMI does not offer product in Super Precision class.

- Question: How can I calculate the friction force (required thrust force) of Linear Guides?

- Answer: Friction force is obtained by the following formula.

F=μ・W+f

F : Friction (N)

µ : Dynamic Friction Coefficient Miniature Linear guides 0.004∼0.006

Linear Guides for Medium and Heavy load 0.002∼0.003

W : Applied Load

f : Seal Resistance (2N ∼ 5N)

-

- Question: Do you have recommended specification of screw for rail mounting?

- Answer: Please use common hexagonal socket head cap screw.

CB Series (Socket Head Cap Screws)

SCB Series (Socket Head Cap Screws/Stainless Steel) - Question: What is your standard seal?

- Answer: There are various seal depending on product as following:

• Miniature Linear guides:Side seal (block side)

• Linear Guides for medium load and heavy load:Side seal (block side) under seal (under block)

• Dust-proof:Side seal x 2 and under seal.

Miniature Linear Guides - Dust Resistant - Standard Blocks, Light Preload

Linear Guides for Medium Load - Dust Resistant - With Double Seals / Metal Scrapers, Normal Clearance - Question: Where is datum of rail and block?

- Answer: Datum is on the side that has marking line for datum of rail and block (with straight groove)

Please see more details about marking line for datum and position in

General information for design and selection of Linear Guides

Usage/ Datum of rail and block for mounting - Question: What is the hardness of rail?

- Answer: Hardness of rail is various depending on production, however, all of them are HRC56 or higher.

Please see more details in each product page. - Question: What is range of operating temperature?

- Answer: Range of operating temperature is between -20∼80°C, however, range of operating temperature for Miniature Linear Guides - Heat Resistant - Short / Standard / Long Blocks, Light Preload is between -20∼150°C, and range of operating temperature for product with plastic retainer is between 0∼50°C (Please search with keyword “Plastic retainer” for more details)

- Question: What is maximum speed?

- Answer: Please do not use speed over 1m/s.

- Question: Were MISUMI Linear Guides finished with hardening treatment?

- Answer: Blocks, rail, and balls of Linear Guides were hardening.

- Question: What grease do you use as a standard for lubricating before shipping?

- Answer: Grease for Linear Guides listed below:

• Miniature Linear guides:Lithium soap grease(Multemp Grease PS2 from Kyodo Yushi Co., LTD)

• Linear Guides for Medium and Heavy load:Lithium soap grease (Alvania Grease S2 from Showa Shell Sekiyu K.K.)

• Heat-resistant Linear Guides: KRYTOXGPL225 from DuPont

-

- Question: Is it possible to use your Linear Guides on the wall, ceiling, or lift up?

- Answer: Yes,

MISUMI Linear Guide have the same load rating at all 4-mounting direction (radial, reverse radial, horizontal) Therefore, mounting direction has no effect to load rating. - Question: I found oil leak out from blocks when using in vertical direction.

Does it effect to performance? - Answer: No effect to performance.

MISUMI Linear Guides were not closed system, so oil can be leaked out. Anyway, it is recommended to shorten the interval of re-lubrication when using in vertical direction. - Question: I want to reduce the friction as much as possible, should I remove the side seal?

- Answer: Removing the side seal may lead to bad movement, so we do not recommend removing side seal.

Please check on other product that has lower friction than Linear Guides (Ball slide guide, Cross roller table type) - Question: Can I use Linear Guides by connecting of 2 rails?

- Answer: It is not recommended to connect 2 rails.

Because the end face of them may not fit enough, it may result in bad movement at connecting area. - Question: Can blocks be added or changed?

- Answer: Blocks can be added or replaced only Linear Guides for medium load and light preload type. Other type cannot be added or replaced block. (All Miniature Linear guides cannot be added or replaced block)

<Linear Guides with light preload>

• Linear Guides for Medium Load - Stainless Steel - With Plastic Retainers, Interchangeable, Light Preload

• Linear Guides for Heavy Load - Stainless Steel - With Plastic Retainers, Interchangeable, Light Preload

• Linear Guides for Super Heavy Load - Stainless Steel - With Plastic Retainers, Interchangeable, Light Preload - Question: Do balls fall out when removing from blocks?

- Answer: Balls do not fall out of MISUMI linear guides when removed from rails as the blocks are equipped with ball-retainers. However, the balls may fall out by rapidly removing blocks from the rail or inserting the rail into the block at an angle. Remove and install the blocks with caution.

- Question: Please explain about how to maintenance the Linear Guides.

- Answer: Please re-lubricate Linear Guides periodically for smooth operation and longevity.

Recommended Lubrication Intervals: Every 6 months or every 3 months when travel distance is extensive, or every 1000km. If the grease degrades or gets contaminated faster depending on the operating environment, please shorten the lubrication interval as needed. - Question: Please explain how to re-lubricating.

- Answer: Please re-fill grease via grease nipple.

For Miniature Linear guides that do not have grease nipples, please apply grease directly to the rail groove and slide the block to blend it in. - Question: Can the fall-prevented clips attached to the rail when shipped, be used as a stopper?

- Answer: No, clips are used for shipping, not be used as stoppers.

- Question: I have purchased Linear Guides with 2 parallel axes (WC) totally 4 pieces (2 set)

There are number 1 and 2 written with blue and black ink on product. How should I assembly them? - Answer: Please assembly 1 to 1, and 2 to 2.

Numbers were written at 2 positions: inner box and wrapping vinyl of Linear Guides. - Question: How should I re-lubricate Miniature Linear guides that do not have grease nipples?

- Answer: Please apply grease directly to the rail groove and slide the block to blend it in.

- Question: Which position do grease nipples mounted on Linear Guides for Medium load and heavy load that contain 2 blocks.

And can I change the mounting position later? - Answer: Grease nipples were mounting at the position that do not contact either block and placed in direction that point to the end of rail before shipping. For Linear Guides with 3 or 4 blocks, please see more details in product drawing in each product page.

In addition, grease nipples were mounting with screw, so it is easy to change position by removing the screw.

-

- Question: I want to know about increment range of rail.

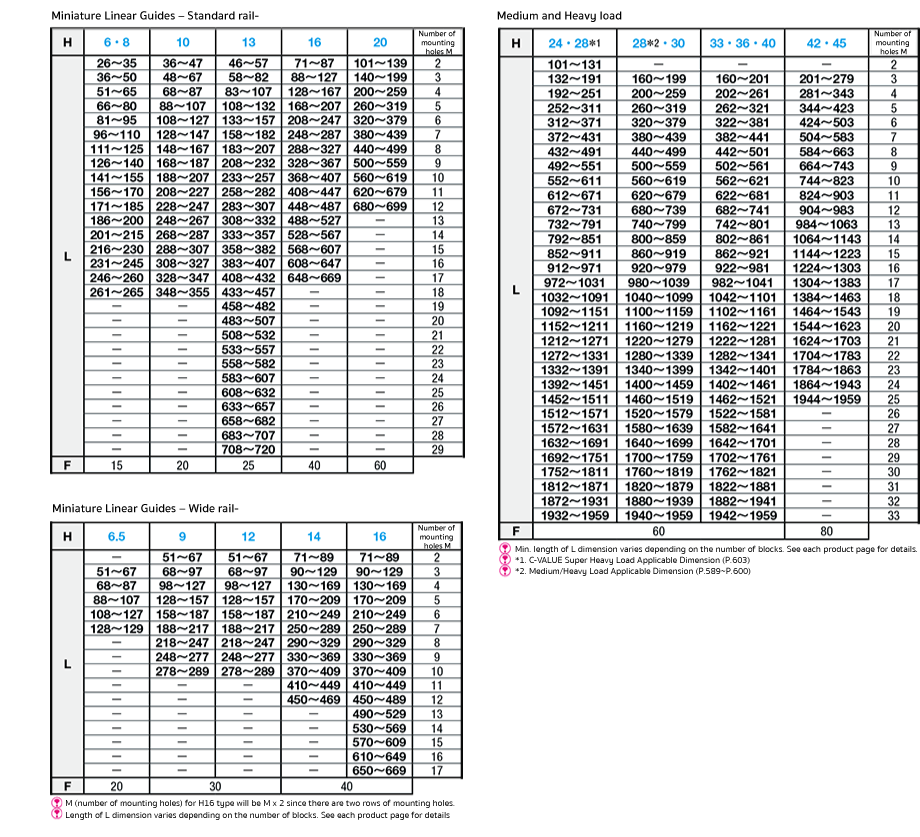

- Answer: Length is dependent on type. Length increment is 1mm between 40mm∼1960mm.

- Question: How can I calculate the length from end face of rail to the center of first hole (G-dimension) when specify L-dimension

- Answer: Please calculate by the following table.

G-dimension = (L-dimension - ( (Numbers of hole -1) ) × F-dimension) ) / 2

Number of mounting holes is shown below:

- Question: Can I order rail with some length not listed in catalog?

- Answer: Please send us a request for quotation via Quotation request for item not listed in MISUMI FA Catalog service. We will check and advise if it is available.

- Question: Do you offer product for fixing (maintain) block in specified position?

- Answer: Yes, please check on Clamp Lever for Linear Guides:

• Linear Guide Clamps - For Miniature Linear Guides(SECK SECWK)

• Linear Guide Clamps - For Medium/Heavy Load Linear Guides(SVCN SVCK)

※Clamp lever for Linear Guides C-Value is not available. - Question: Can I purchase the side seal of return cap of block separately?

- Answer: No.

- Question: Is there any product used for height adjusting of Linear Guides?

- Answer: Yes, please check on Height Adjusting Blocks for Linear Guides. There are available for each size of Linear Guides except Linear Guides for heavy load and Linear Guides for extremely heavy load.

• Height Adjusting Blocks for Linear Guides - Economy Type

• Height Adjusting Blocks for Linear Guides - High Precision Type

• Height Adjusting Blocks for Miniature Linear Guides - Standard Rail Type - Question: Do you offer the non-magnetic Linear Guides?

- Answer: No.

You can create the non-magnetic Linear Guides for light load by using the combination of the Aluminum extrusion and rail for Aluminum extrusions. - Question: Do you offer special type greases?

- Answer: Yes.

Special type of greases listed below:

• L-Type (ET-100K (Kyodo Yushi) )

• G-Type (LG2 (Nihon Seiko) )

In comparison with standard grease, L-Type is excellent in adhesion and adhesive power. G-Type is low particle generation grease, used for cleanroom. - Question: Can I order product with no grease filled?

- Answer: Yes.

Please send us a request for quotation via Quotation request for item not listed in MISUMI FA Catalog service.

(Not available for C-Value) - Question: Do you offer rail and block separately?

- Answer: Rail and blocks cannot be order separately.

This is because blocks and rails guarantee their accuracies as sets of blocks and rails.

Only plastic retainer available for separately order. - Question: Do you provide mounting bolts as attachment?

- Answer: No, please request them upon your purchasing.

Bolts only provided as attachment for Miniature Linear guides (H6 H8 etc.) - Question: Do you offer cap for rail mounting hole?

- Answer: Yes, please check on Slide Guide - Rail Mounting Hole Caps【100 Pieces Per Package】【100 Pieces Per Package】(PACK-SGLC)

However, available for product with M3 M5 M6 hole only. - Question: Do you offer bellow type Linear Guides?

- Answer: No.

- Question: Can I order the standard grease filled with product on shipping in separately?

- Answer: Yes, below is standard grease for Miniature Linear guides and Linear Guides for Medium load and Heavy load. Each product has 2 types of greases.

• Standard grease filled in Miniature Linear guides:Multemp SRL from Kyodo Yushi

• GRSPS2 (80g)

• MPS2-25 (2.5kg)

※Above product is not listed in FA Catalog, but available for order or request quotation via <WOS> by input model code.

• Standard grease filled in Linear Guides for Medium load and Heavy load:

Shell Alvania Grease S

• ALVANIA-S-2-400G

• ALVANIA-S-2-16KG

※ Please see more details about quantity and volume in each product page. - Question: Do you offer MISUMI original product?

- Answer: MISUMI original product are Blocks with Knock hole)/ Rail with Knock hole/ 1-sized up mounting tap/ Super long blocks.

- Question: Do you offer product with plastic retainer?

- Answer: There are no Miniature Linear guides with plastic retainer.

It is available in some type of Linear Guides for medium load and heavy load.

-

- Question: Please explain how to input the model code for product with 2 or more blocks.

- Answer: Please see the below example:

※Example of model code for Miniature Linear guides SSEB

• 1 block:SSEB10-155

• 2 blocks:SSE2B10-155

• 3 blocks:SSEB10-155-B3

• 4 blocks:SSEB10-155-B4

• 5 blocks or above:Please send us a request for quotation via Quotation request for item not listed in MISUMI FA Catalog service (May not available for some block or length configs) - Question: I have selected the length of rail within the range, but it displayed as model code error.

- Answer: It is possible that model code of selected product is not matched between model code in system (select product from length shown in Specification table) and specified code (Specify product length that does not exist in specification), so system displayed as model code error.

Example of product model code) SSEB10-55

Example of specified code) SSEBL10-59

Please verify both selection step if you input correctly or not. - Question: Can I ask about the substitute product of MISUMI Linear Guides for product of other manufacturer?

- Answer: Please contact our Customer Service Team via Technical support for Mechanical products

We can check model code and provide some advice.

Automation Components

- Linear Motion

- Linear Shafts

- Shaft Supports

- Shaft Collars

- Linear Bushings

- Ball Guides

- Spline Shaft

- Oil Free Bushings, Washers

- Oil Free Plates, Guide Rails

- Linear Guides

- Cable Carriers

- Ball Screw

- Support Units

- Lead Screws, Slide Screws

- Cross Roller

- Slide Packs, V Guides, Linear Rails

- Actuators

- Other Linear Motion Related Components

- Bellows

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy